What is SAP PP Module | Production & Planning | SAP PP Overview

What is SAP PP Module | Production & Planning | SAP PP Overview

Grade a+ Course

Content is Benchmarked by SAP

Trained 10k+ Students

10000+ candidates are trained from our Institute in the last 10 years.

We are based in New Jersey, USA

26 Wills Way, Piscataway, NJ, USA 08854

4.8+ rating

Highly satisfied students

We are based in New Jersey, USA

26 Wills Way, Piscataway, NJ, USA 08854

Level 3 – Expert Level Course

Course is designed to prepare you to become a SAP Consultant

Trained 10k+ Students

10000+ candidates are trained from our Institute in the last 10 years.

4.8+ rating

Highly satisfied students

What is SAP PP Module | Production & Planning | SAP PP Overview

What is SAP Production & Planning

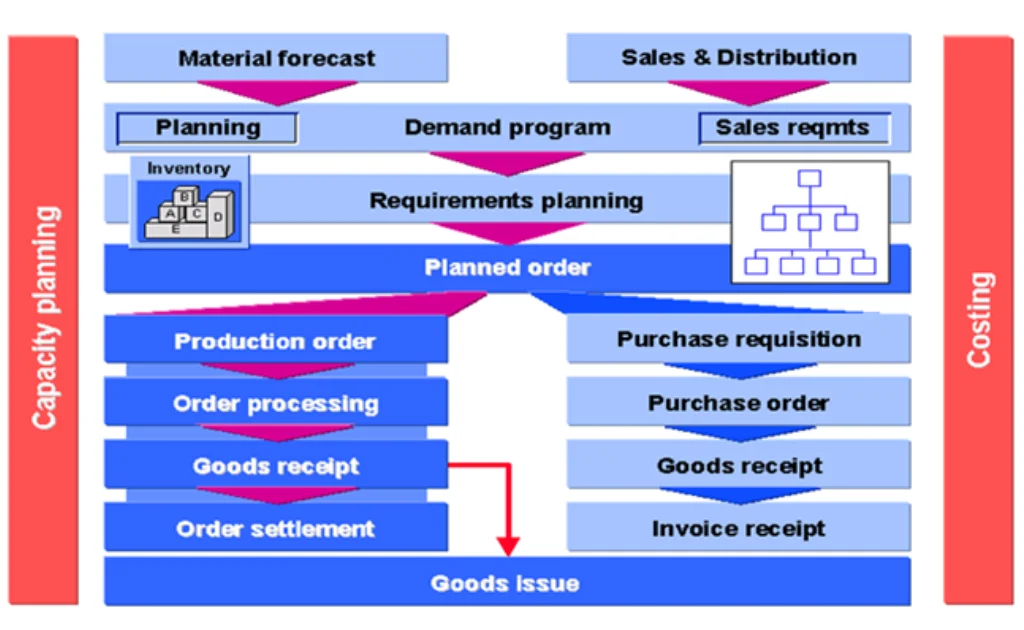

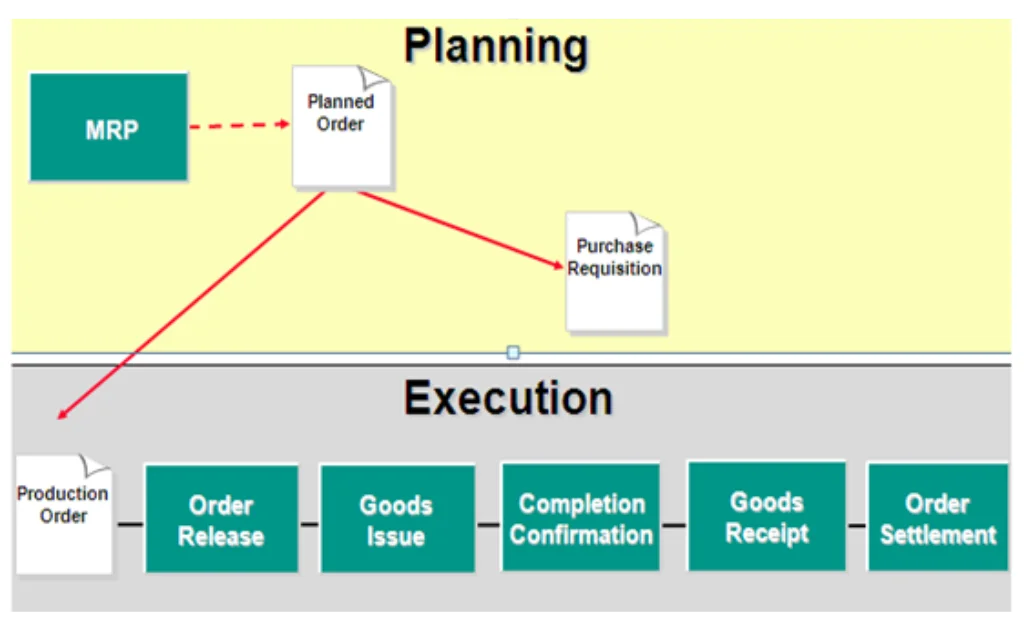

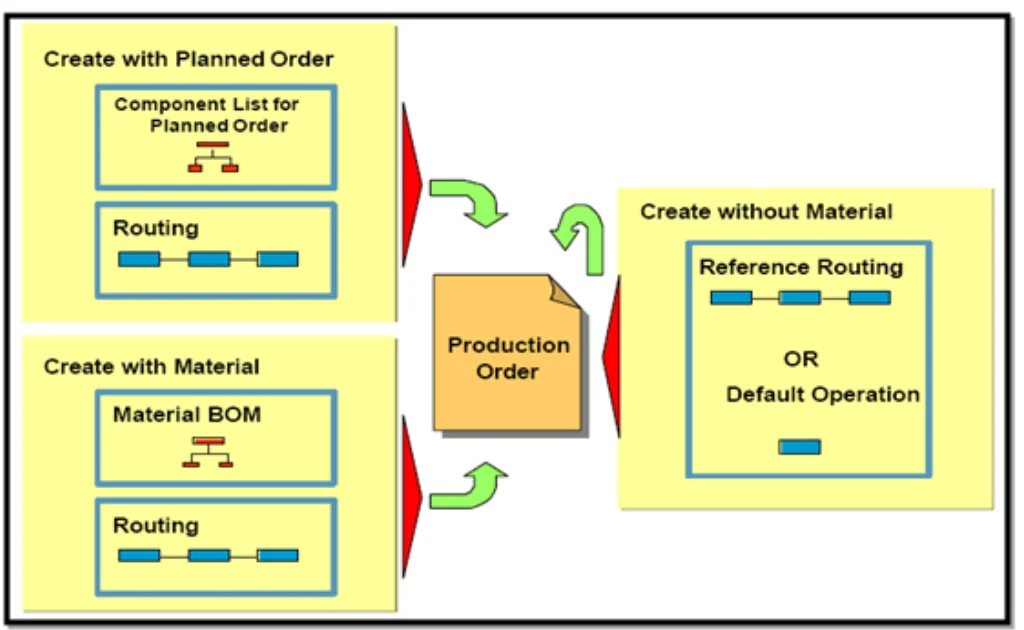

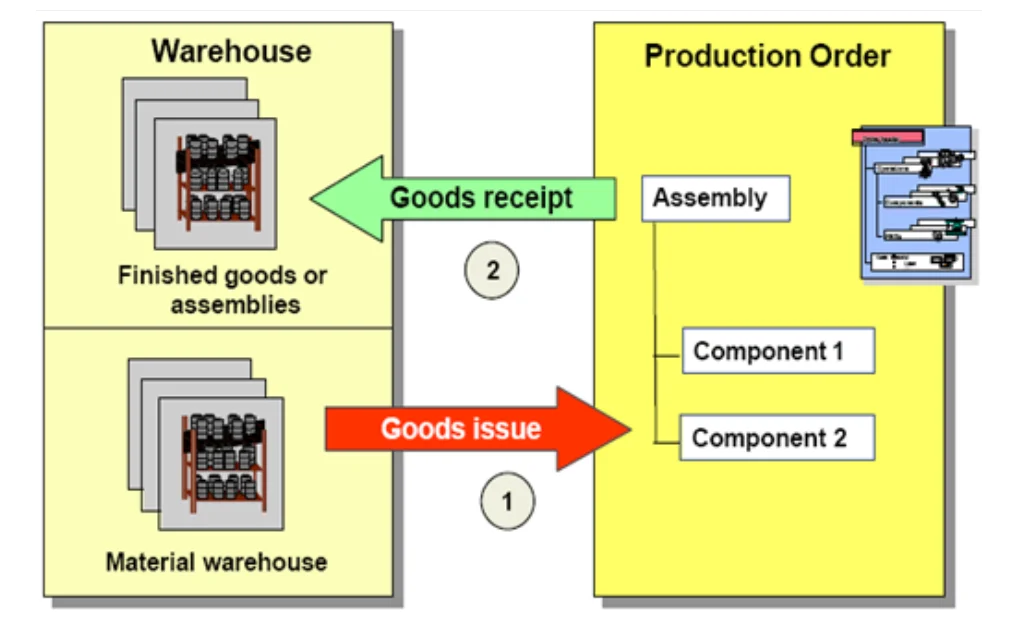

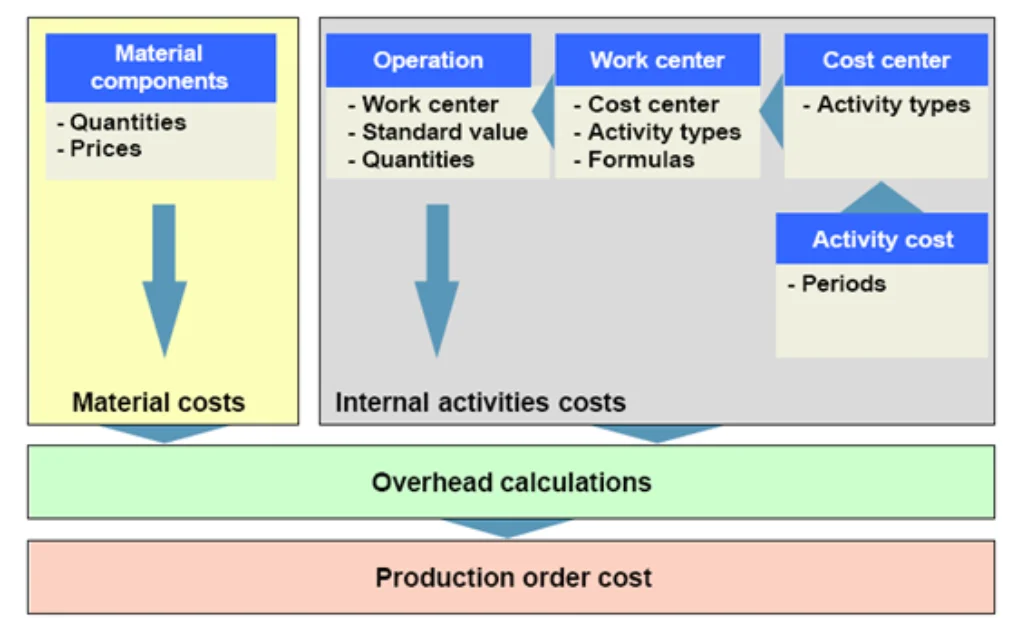

SAP Production Planning (SAP PP) is the heartbeat of manufacturing in the SAP ecosystem. It empowers businesses to efficiently manage the production lifecycle—from demand forecasting and material procurement to order execution and cost control. By integrating with SAP modules like SD, MM, CO, and QM, SAP PP ensures end-to-end visibility, optimized resource utilization, and timely product delivery.

Whether you’re dealing with Make-to-Stock (MTS), Make-to-Order (MTO), or Repetitive Manufacturing, SAP PP delivers a robust framework for planning, scheduling, and controlling all production activities.

Overview of Production Planning (PP)

- SAP PP (Production Planning) is a core module of SAP ERP for manufacturing companies.

- It is tightly integrated with other modules like MM (Materials Management), SD (Sales & Distribution), and CO (Controlling).

- Ensures manufacturing efficiency through planning, execution, and monitoring.